Featured Products

-

T drill strings

It´s all in the thread

The T drill string has a tough thread system. In fact, it’s robust enough to prevent product breakage in the blast hole. Which means you can shift your focus from all those time-consuming rod and shank changes to maintaining a much leaner stock.

Our drilling system comes in five dimensions: T35, T38, T45, T51 and T60. T speedrods are ideal for bench and production drilling, and are available as extension or drifting drill rods.

What’s more, the T range of shank adapters will work wonders with your equipment – whether you’re running an drilling rig, or some other brand.

-

COP M series

Ground breaking technology

Our COP M series 6″, 7″ and 8″ hammers are designed and built to perfection. They are faster, lighter, more service friendly and longer lasting than ever before.

COP M6 This is the fastest 6″ DTH hammer on the market. It covers the most common hole diameters, from 165 mm to 171 mm.

COP M7 The 7″ hammer is an all-new product, designed to bridge the productivity gap between 6″ and 8″ hammers. The ideal bit diameters for COP M7 range from 200 mm to 229 mm. Indeed, tests comparing COP M6 and COP M7, using 203 mm bits, show that COP M7 is 27 % faster.

COP M8 The most powerful M-series hammer, COP M8 is 8” and designed for bit diameters from 229 mm to 254 mm.

-

COP Gold series

Transforming DTH drilling excellence

At its core, COP Gold reflects a commitment to innovation, reliability, and enduring performance, reshaping the DTH drilling landscape with advanced technology.

In demanding environments, COP Gold stands as a symbol of superior craftsmanship, purpose-built to endure the rigors of DTH drilling. Its robust design guarantees longevity and reliability, surpassing traditional counterparts.

-

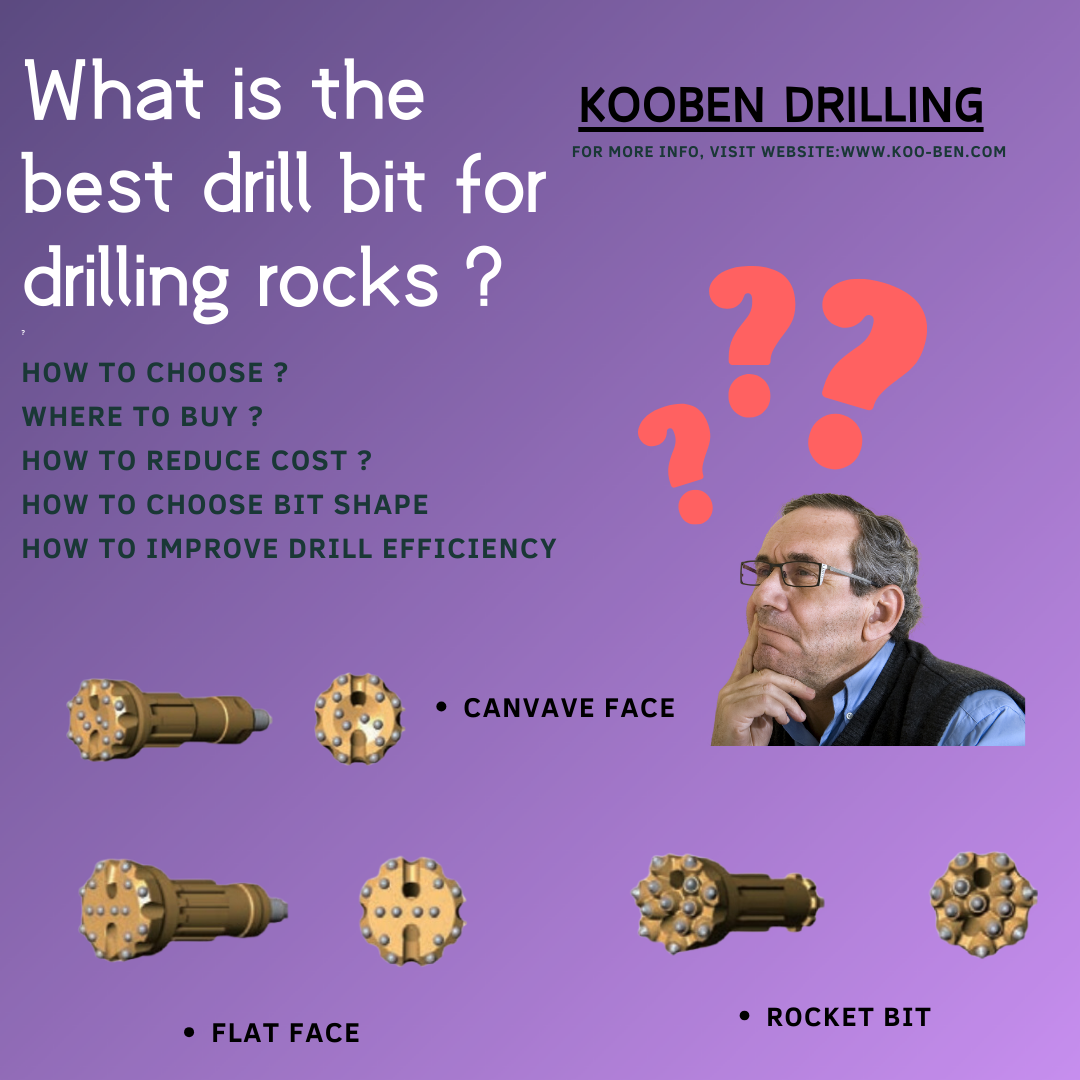

Surface Drill Bits

The bits are built to take on any rock, from hard to soft, and from abrasive to non-abrasive. These bits last much longer. They give the drillers more meters before the first regrind, and many more meters between the regrinds. With the bits, drillers are guaranteed to get more performance from each bit.

-

COP RC45

COP RC45

This is the smallest, fastest and lightest Reverse Circulation (RC) hammer available, providing you with easy handling and outstanding drilling performance. With its unique air chambers design, pressure builds up faster allowing the piston to strike faster. The result is marginally lower impact energy and leads to a great increase in power output and a marked improvement in penetration rate.The COP RC45 features a unique air cycle distribution. This design makes it easy to service and replace tubes since you don’t have to disassemble the hammer. Quite simply this means minimum down-time and maximum time producing samples.

●Can be handled by one man

●Simple design for easy maintenance and minimal downtime

●Lighter weight for easier handling

●Higher frequency for maximum power output

●Improved fuel efficiency

●Long service life

-

Air Filters

Equipped with industry-shaping RadialSeal™ system, advanced media, and stable structural support, these air filters for Mann+Hummel® Entaron air cleaners are built to perform and provide effective engine protection, in a wide-range of challenging on- and off-road environments.

-

DTH drill bits

●Up to 20% longer service life

●Fewer interruptions

●Smaller footprint

-

DTH 5 Hammers

DTH 5 hammers give you twelve configurations in one system. So, whatever your specialty is, regardless of what customers demand, you will always have the perfect hammer for any job. That opens new opportunities to grow a more profitable and competitive business. At the same time, with all your needs covered by one range, you can minimize spare parts while maximizing your areas of operations.

In short, DTH 5 hammers handle all types of drilling in any type of rock formation and can be customized to handle high- and low-impact energy and airflow. You can trust them to work seamlessly with all leading rigs and compressors – but of course, the way to optimize them is to use them with other equipment .

Also, you can expect DTH 5 hammers to be super-efficient and premium. Its predecessor was a clear market leader, yet this new range assures you a higher penetration rate, and the hammers last longer.

Another upside is better working conditions for operators due to fewer stops and heavy lifts. Finally, since the hammers last longer, you don’t need as many – and that reduces your footprint.

About Us

Forged by experience and driven by insight, Kooben was founded to bridge the gap between elite Chinese manufacturers and global customers. Our leadership team is comprised of seasoned veterans from industry giants like Epiroc, Sandvik, and Zega, bringing unparalleled expertise in R&D, supply chain, and product application. We act as your strategic procurement partner, using our deep technical understanding to meticulously vet and deliver customized drilling solutions that offer superior performance and value. With Kooben, you gain a curated competitive advantage, backed by a dedicated service team for comprehensive support.