Drill tools

-

Roller Cone Bits Size 10 578″ IADC722 TCI Drill Tools Tricone Bits for Water Well Drilling

Kooben offers a full line of tricone bits. Tricone drill bits are available in new steel tooth and tungsten carbide insert, size from 3 3/8″(85.7mm) to 26″(660.4mm) for use in all formations, with any bearing/seal type, and a wide range of additional custom features.

-

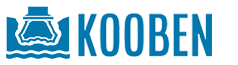

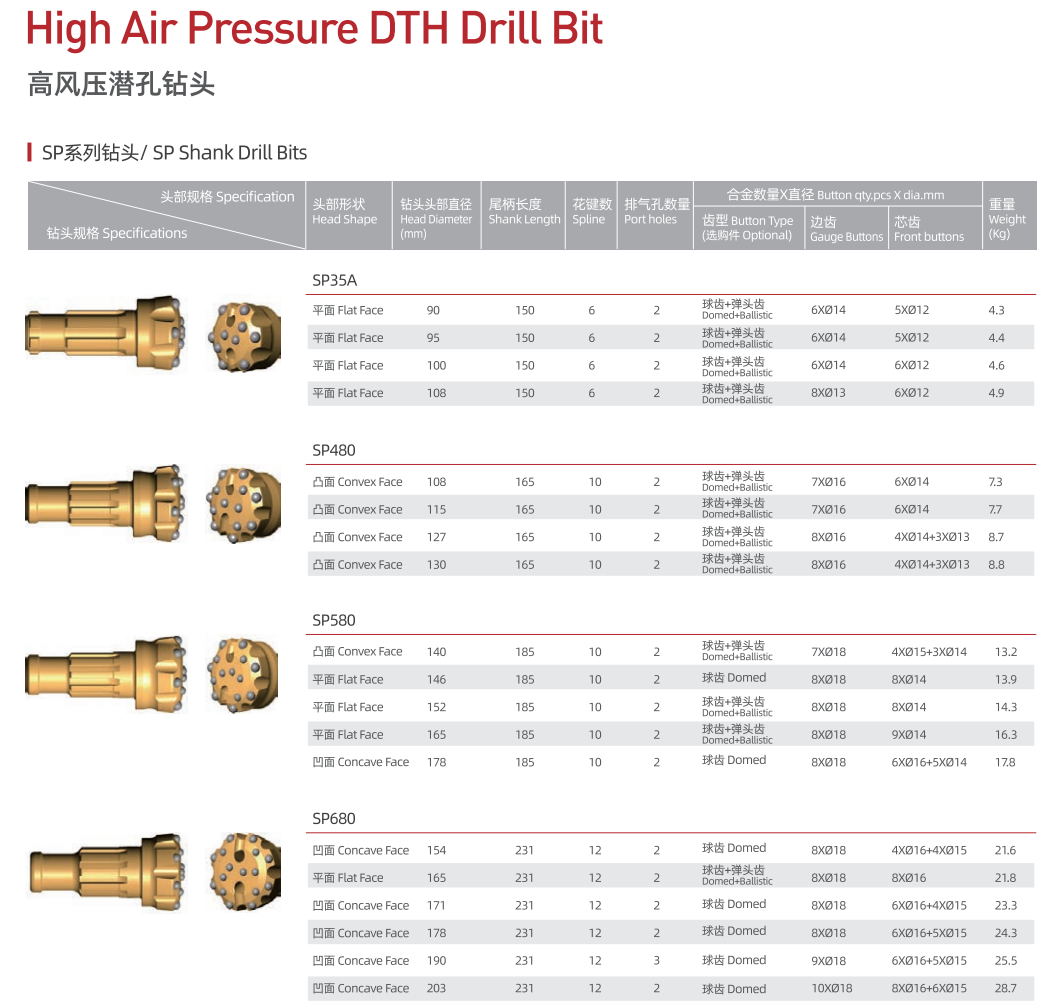

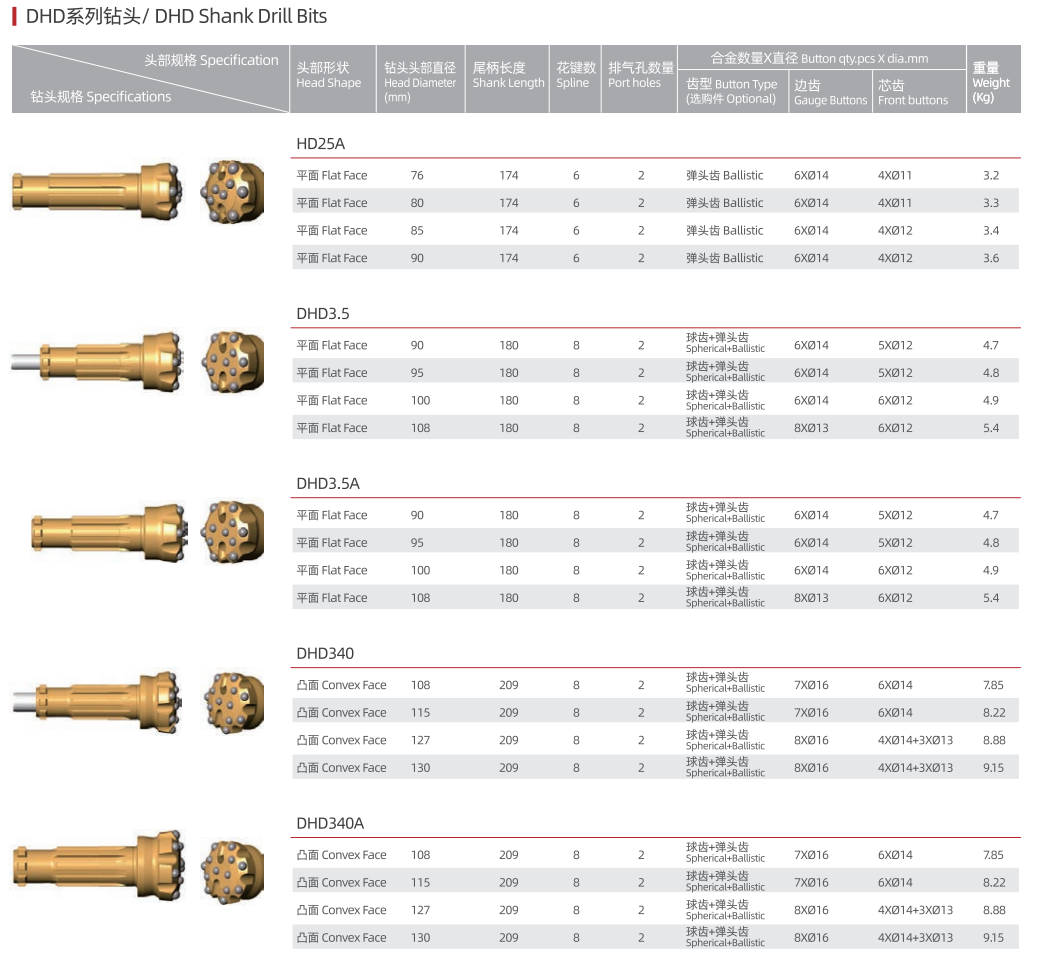

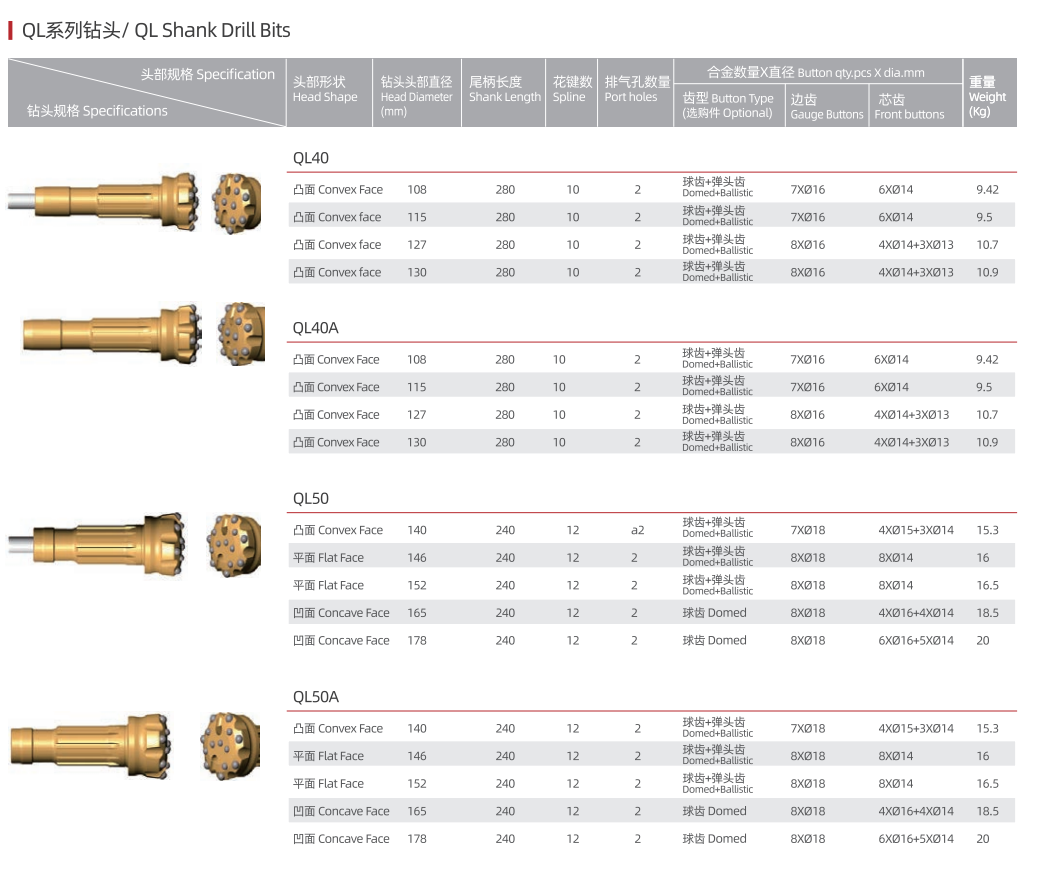

DTH Drilling Bits drilling tools

What is the best drilling bit for drilling rocks?

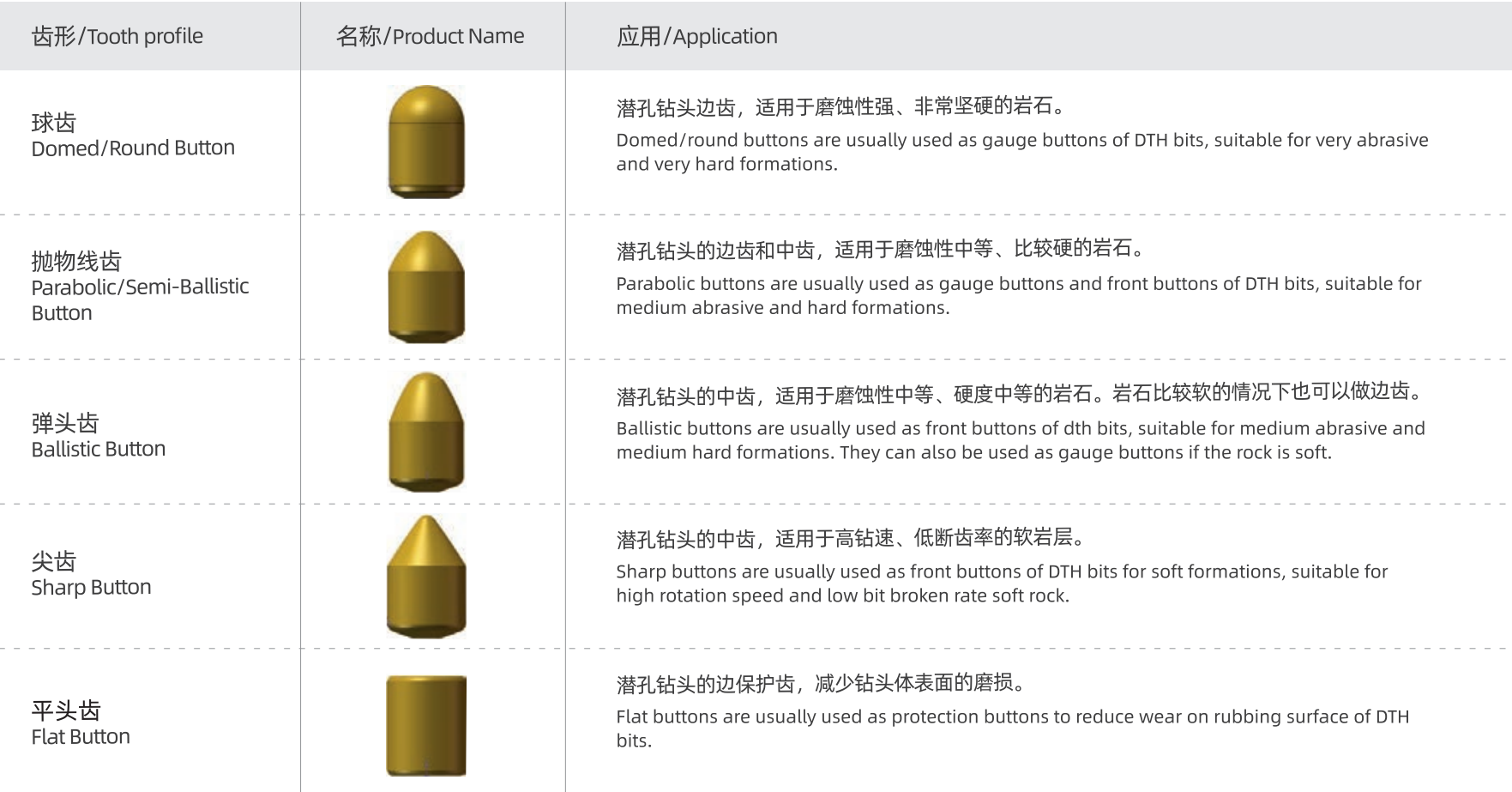

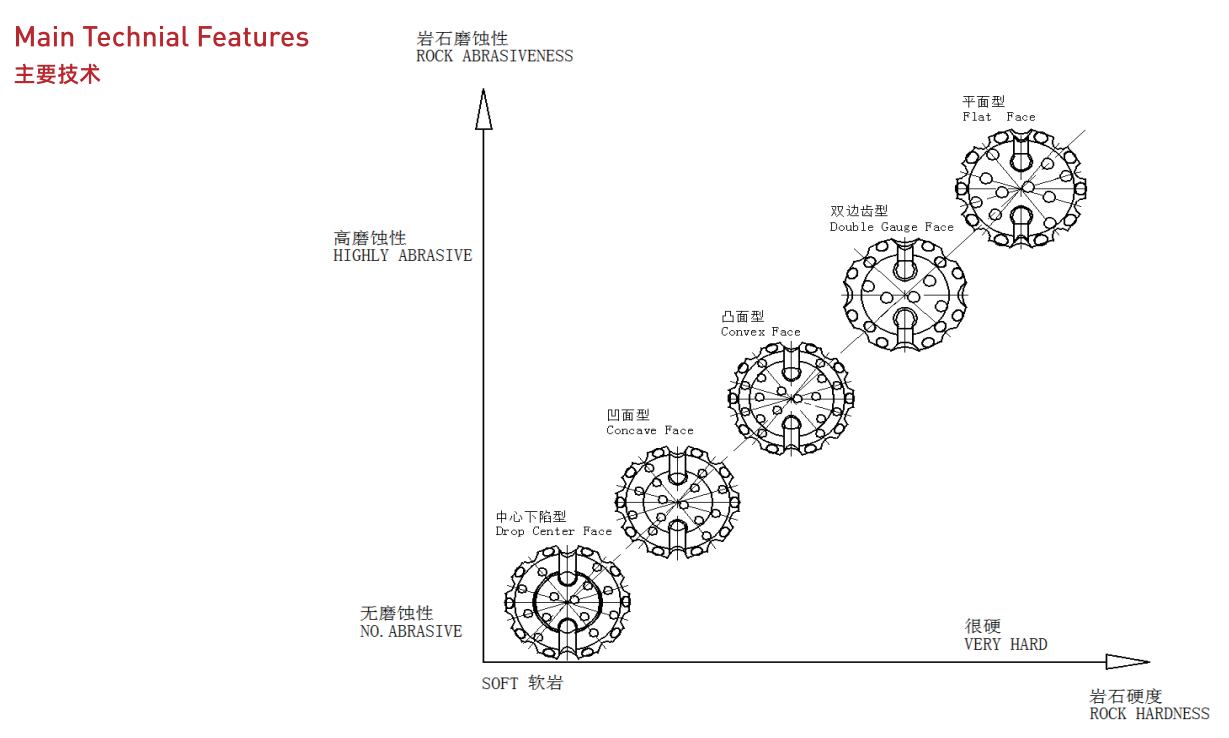

We usually face many questions when choosing the best button bit for rock drilling. You don’t know what shape drill bit to choose? flat? Convex or concave? So it’s not very clear about the choice of alloy tooth shape? Should I choose ball teeth or ballistic teeth? Or sharp teeth or flat teeth? Drill bit selection is crucial for rock drilling as different types of rock require different types of drill bits to ensure efficient drilling process. There are several key factors to consider when choosing the best drill bit.

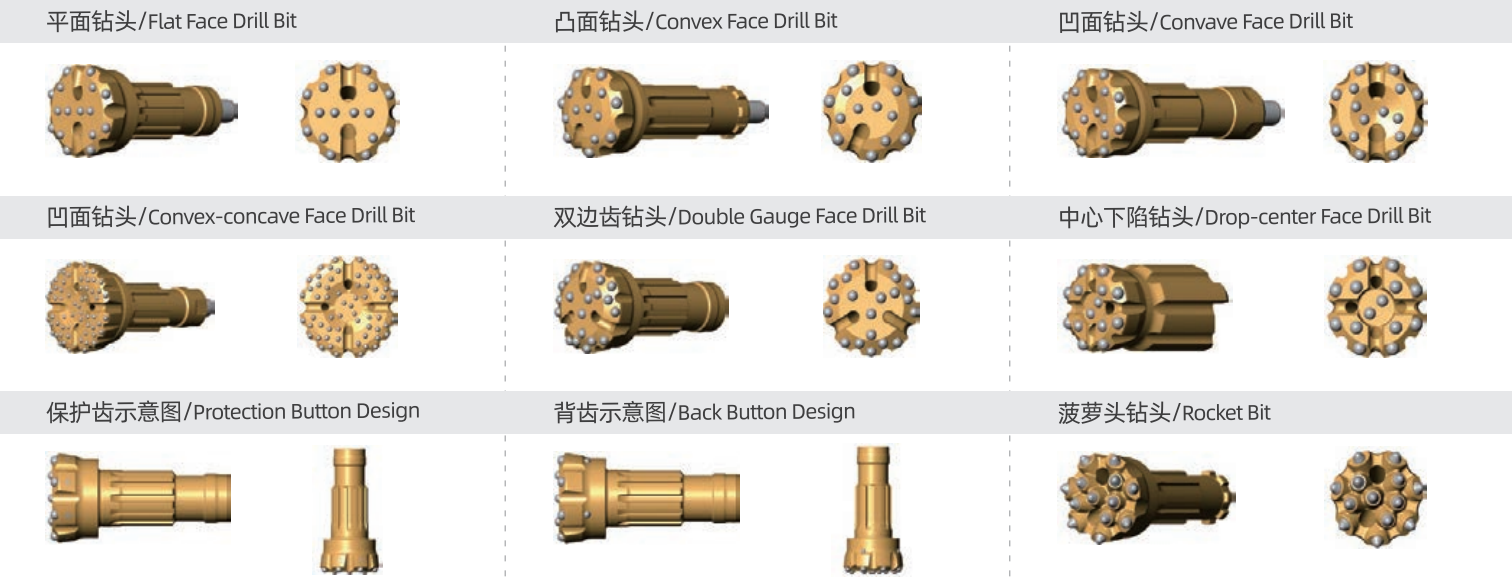

First of all, the material of the drill bit is very important. Tungsten Carbide Mining Rock Ballistic Drill Bits are a commonly used carbide drill bit with excellent wear resistance and corrosion resistance, suitable for various rock drilling jobs. Advantages of this drill include efficient drilling speeds, long life and consistent performance.

Secondly, the design of the drill bit is also an important factor affecting the drilling effect. Ballistic Drill Bits and Semi-ballistic button Bits are two common designs, as well as Domed Button and Sharp Button bits. They are suitable for different types of rocks. Ballistic Drill Bits are suitable for soft and medium-hard rock, while Semi-ballistic Button Bits are suitable for hard rock and gravel. Domed bit is suitable for very hard rock. However, the tines are suitable for high-speed drilling and soft rock with low-end tooth rates. Choosing the right design can improve drilling efficiency and reduce maintenance costs.

Finally, when choosing a drill bit, you also need to consider factors such as drill hole diameter, drill bit shape, and the way the drill bit is connected. Depending on your specific drilling needs and rock type, choosing the best drill bit can help increase productivity and reduce costs.

Overall, choosing the best drill bit is crucial for rock drilling. By understanding the advantages, applications and selection methods of drill bits, we can help you to better choose drill bits that suit your needs, thereby improving your work efficiency and saving costs.

Drill Bit Design

Carbide Button Shape Selection:

-

EPIROC drifter SC19 drilling tools

Developed to provide extended service life, without sacrificing it’s proven drilling performance. Recommended service interval of 800 percussion hours.

1.Versatility with two different stroke settings to optimize performance even as hole sizes and rock conditions vary

2.Reliability with optimized rock contact, while simultaneously protecting the rock drill from harmful energy recoils

3.Reduced running costs with increased service life

-

SHANK ADAPTER TUBES

Atlas Copco COP 1238 Part Number Thread Out... -

Raetrac Button Bits

R32 Part Number Head Shape Head Diameter(mm)... -

Normal Button Bits

R25 Part Number Head Shape Head Diameter(mm)... -

HAMMER

DHD3.5 No. Descprition Part Number Weight(kg... -

DRILL ROD

Box-Box Adapter Tube Part Number Adapter ... -

Adapter Tube

Box-Box Adapter Tube Part Number Adapter ...