Products

-

Lube Filter Spin-On LF14001NN Oil Filter

Fleetguard® LF14001NN premium lube spin-on filter features uses 2-in-1 NanoNet® and StrataPore® media to provide extended service intervals up to 100,000 miles while meeting or exceeding engine requirements. This media manufacturing technology provides the following advantages for our combination filter: higher particle removal efficiency, increased contaminant holding capacity, reduced flow restriction, especially under cold-start conditions, reduced CO2 footprint, and lower total cost of ownership

Is air filter necessary on air compressor?

Industrial compressed air systems rely on proper filtration to ensure air purity and reliability. Choosing the right air filter will not only boost the efficiency of your compressor and produce safe airflow, but also reduce energy costs and protect workers from dangerous particulates and contaminants.

The purpose of the air filter is to filter various impurities in the air to ensure clean air enters the engine, allowing for more complete combustion and smooth air system. A high-quality air filter is an important component to ensure the normal operation of the engine.

Kooben Company provides a variety of high-quality metal air filters, plastic air filters, square air filters, air filter elements and accessories, which are widely used in various types of commercial vehicles, passenger vehicles, engineering machinery, mining machinery, generator sets and other fields. Our company uses high-quality raw materials, advanced technology, and carefully designs to meet the strict requirements of various customers for air filters. We can also develop and design according to customer requirements.

-

Yuchai primary air filters AF4878

Fleetguard® AF4878 Magnum RS™ radial seal primary air element is designed to meet the rugged demands of equipment operating in the harshest environments. The Magnum RS offers unique features that provide significant benefits for longer service life and optimum performance when the job demands it.

-

Primary air filters element AF55550 with factory price

Fleetguard® AF4878 Magnum RS™ radial seal primary air element is designed to meet the rugged demands of equipment operating in the harshest environments. The Magnum RS offers unique features that provide significant benefits for longer service life and optimum performance when the job demands it.

-

Shantui Bulldozer SD32

320 HP

High-efficiency push factor

Engine model: Cummins NTA855-C360S10

Net power: 235 kW/320HP/2000 rpm

Operating weight: 37.2 t

-

XCMG Articulated Dump Truck XDA45

XDA45 Articulated Dump Truck is designed for use in mining, quarry, water conservation, harbour, brown field and construction sites. It has a powerful drivetrain, superior hauling performance, excellent manoeuvrability and efficiency making it suitable for the wide range of applications. The product is designed to run continuously in an operating environment from -25℃ to 40℃ and meets Euro Ⅲ emission standard.

-

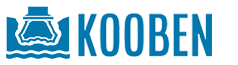

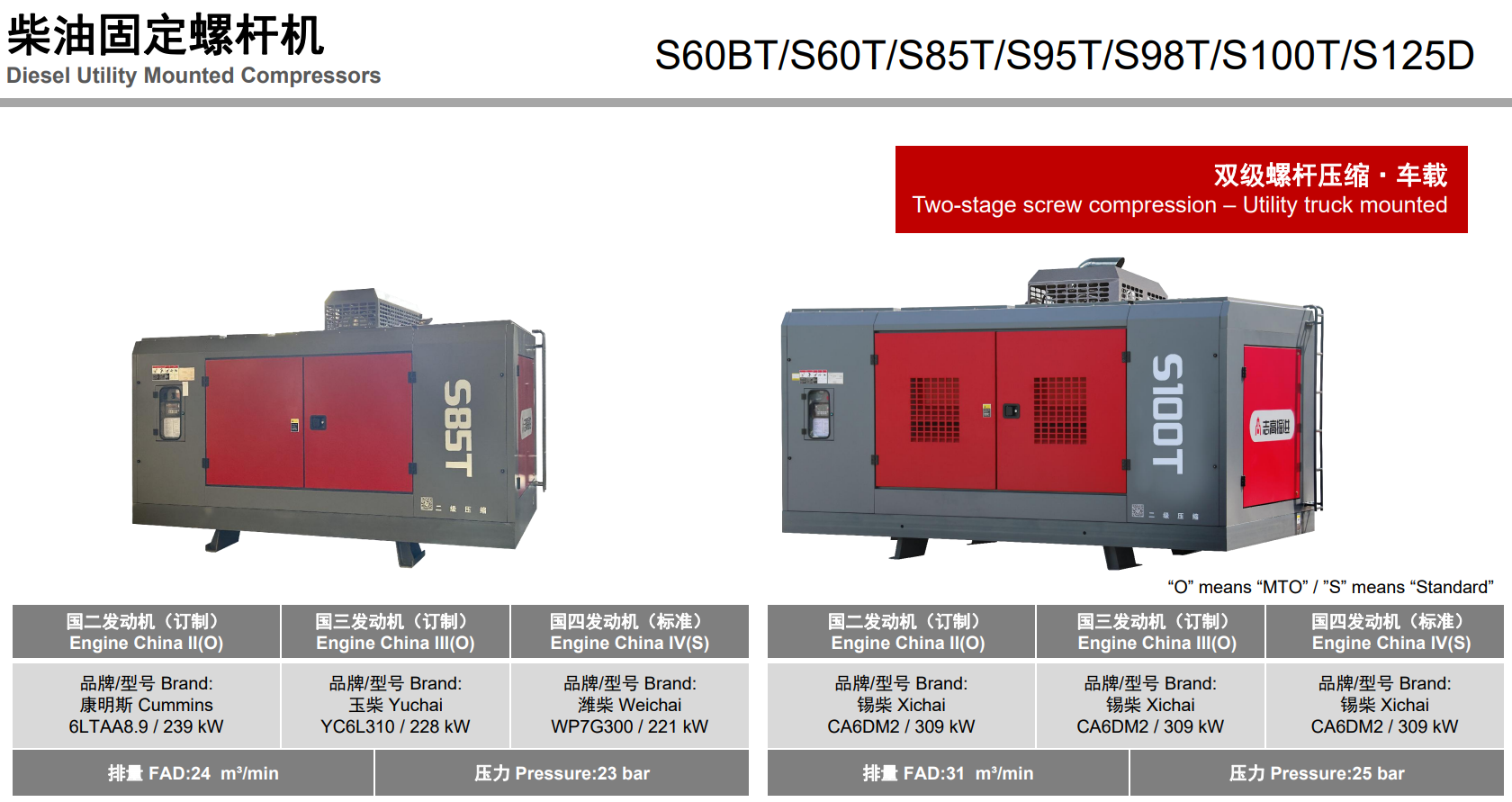

Diesel portable air compressor S125D

Main features of our diesel screw air compressor S125D:

Fully automatic control system and protection system;

Capacity control without oversight;

Luxury luminous microcomputer instrument panel;

Adopted high-level filters with safety filter;

Cummins or Yuchai diesel engine for you to choose;

Very competitive price!

-

Yuchai Oil filter M3000-101224A

The performance of the oil filter directly affects the performance of the engine and plays a key role in the normal operation of the engine. Kooben’s oil filters have high filtration accuracy, low flow resistance and long life. Kooben oil filters are available as full-flow and split-flow combined filters, centrifugal rotor filters, and can be equipped with a base for connection to the engine according to the customer’s requirements. Under the premise of guaranteeing engine performance, we can provide greater protection for the engine to reduce your maintenance costs.

-

Water Well Drill Rig Fy180

Water well drill rig machine FY180 product features:

FY180 water well drilling rig features: 1. Engine: well-known brand Yuchai

-

Separated Dth Drill Rig Zgyx-412/412-1

ZGYX-412/412-1 drill rig upgrades the operation platform, tramming components, hydraulic system, feed beam, & rotary head from the original 410C to optimize the functional capability of the drill rig. Piston tramming motor greatly increases the work life of tramming mechanism. Upgraded operation platform can be controlled by one operator instead of two, to increase the work efficiency while lowering drilling cost.

-

Separated Dth Drill Rig A5

Blast hole drilling rig is used most frequently in the mineral exploration industry among all the mining drilling equipment. This blasting rig is penetrating the rock via a air driven hammer and hammer bit. Its power supply comes from independent air compressor or on deck compressor or rock drill. The cuttings is blown out of hole by air It normally requires mining drill rigs have capacity of 15- 30m depth with 100 – 200mm blast hole diameter. Hard rock blast hole drill machine is dedicating to offer Mining Rigs with the latest and most advanced technology to ensure the most efficient of blast hole drilling and highest reliability. Our Blast hole drill is in various rod handling capacities, sizes, and angle drilling options. Known for excellent performance, efficiency, and low maintenance, our range finds application in mining and exploration industry.

-

Water Well Drill Rig Fy450

FY450 type water well drilling rig features:

1. It is an efficient and multifunctional groundwater drilling equipment, which can be used for drilling water wells, agricultural irrigation wells, geothermal wells and other wells. It is especially suitable for water intake projects in mountainous areas and rock formations.

-

ZGYX-420 Separated Blast hole drilling rig small model

ZGYX-420 drill rig upgrades the operation platform, tramming components, hydraulic system, feed beam, & rotary head from the original 420C to optimize the functional capability of the drill rig. Piston tramming motor greatly increases the work life of tramming mechanism. Upgraded operation platform can be controlled by one operator instead of two, to increase the work efficiency while lowering drilling cost.

With larger displacement single motor, compact size & large rotation torque, the rotary head adjustable according to different work conditions & requirement, greatly increasing drilling efficiency

All controls integrated on the control panel for convenient operation,higher work efficiency & lower drilling cost, safer and more comfortable operation.