ZEGA D480A DTH Cummins engine 406kw drill rig with hole range 152-203mm

Technical parameter

| Model | ZEGA D480A | Hole range | Φ178 - 203 mm |

| Suitable DTH hammer sizes | 6/8 inch | Drill pipe handling capacity | 4+1 |

| Drill pipe outer diameter | Φ114 mm | Drill pipe length | 7m |

| Hole depth | 35m | Rotation speed | 0-80 rpm |

| Max. torque | 5600 N.m | / | / |

|

Engine |

|||

| Engine model | Cummins QSZ13 | Rated power | 406 kw |

| Emission standard | Tier IIIA | Fuel tank capacity | 750L |

|

Air compressor- HR2.5/DGH2000 |

|||

| Maximum working pressure | 25 bar (362.5PSI) | Rated F.A.D | 33 m³/min(1100cfm) |

|

Feed beam |

|||

| Hydraulic motor | Hydraulic cylinder +steel wire | Total length | 7475 mm |

| Travel length | 7600 mm | Feed extension | 1300 mm |

| Maximum feeding rate | 0.88m/s | Max. Feed force | 34.5KN |

| Max pull up force | 67.6 KN | Tramming speed | 3km/h |

| Traction force | 156.2 KN | Hill climbing ability | 25° |

| Track frame oscillation angle | 士10° | Ground clearance | 420 mm |

| Weight | 25000 kg | Dimension | 11560*2700*3560 mm |

ZEGA D480A vs FlexiRoc D60 drill rig for compressor and engine

| Model | ZEGA D480A | FlexiRoc D60 |

| Engine | Engine CUMMINS QSZ13 406kW | Engine CAT C13 354kW |

| Rotation torque | 5600 N.m | 5800 N.m |

| Hole range | 152-203mm | 140-165mm |

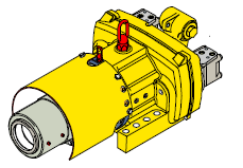

Rotation unit comparison

ZEGA D480A heavy duty rotation unit, torque up to 5600 NM,two rotation motors for better power output and with better reliability

FlexiROC D60 rotation unit structure is more complex, maintenance and running cost very high

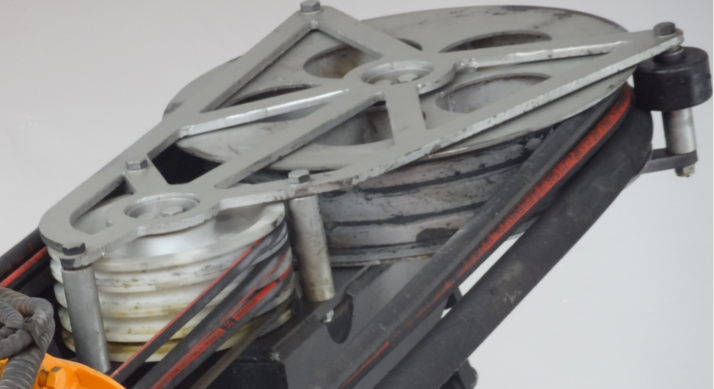

FLOATING HOSE REEL

ZEGA D480A, ZEGA own developed and designed floating hose reel protecting hydraulic hoses, and prolonging the service life.

FlexiROC D60 easy for hoses to tear and wear, high costs to replace!

RHS

ZEGA D480A standard with 7,000 mm drill rod feed beam, saves auxiliary operation time, offers more productivity.

FlexiROC D60 two model of feed beam, 5,000 and 6,000 mm drill

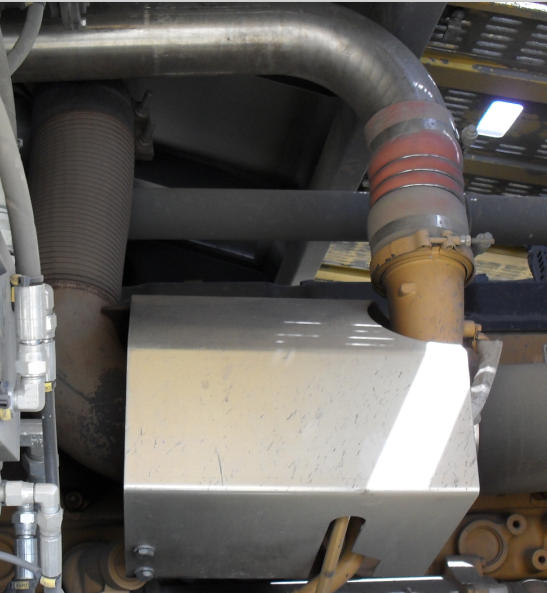

Safety

Zega insolation and hi-temp protection material preventing fire hazard

FlexiROC D60 no effective protection for hi-temp components,easy to cause fire

ZEGA PARTS AND SERVICES

1.Fast response and low service cost,at least 40% less with same quality

2.Lower parts cost and short lead time

3.ZEGA also providing services and replacement parts for competitive brand machines at lower cost and better service for better customer satisfaction!

FlexiROC D60 services and parts

Parts: longer lead-time, higher price

Services: longer response time and higher labor cost

ZEGA D480 drill rig other main features

Ground clearance 420mm,great cross terrain capability

Optional: high altitude and cold aid start-up system

Ergonomic-engineered cabin and game type operation handles, easy to operate

ZEGA own developed and designed RHS, reliable,cost saving and easy to operate,longer drill pipe service life

Heavy duty rotation unit, designed for bigger holes and complex rocks

Single handle controls of tramming, two side tracks synchronized, less wear,longer track life.

Standard with dust collector system, best performance on the market of the same class, easy to use and low cost.

FlexiROC D60 common faults and problems

Impact valve seal easy broken;

Compressor belt difficult to replace;

Pipe storage carousel closed, easy to collect dust

Depth meter inefective frequently,pipe stops at unexpected position to cause unexpected damages of drill pipes

The tramming handle too sensitive for precise control of tramming, for example the risk of tipover when loading or unloading the machines

Ineffective air compressor sensors to cause inability to load

Operating handle buttons failing often and the whole handle must be replaced when button gone

Design fault of pipe carousel causing shorter pipe life

Dust collector too small to dust collecting effectively at high pressure drilling

Application

Mining : Surface drilling, Underground drilling

Quarrying: Aggregate and limestone ,

-Dimension atone industry

Well drilling : Water well

Construction: Civil engineering

Description :

In surface mining productivity is probably the most important factor

− This requires high availability on equipment, good and predictable service life on drilling tools

− Customers usually have good follow up on costs and performance

− Drilling accuracy is an important factor as customers strive to use optimal drill and blast patterns